Why Critical Chloride Thresholds (Ccrit) Matter in Concrete Durability Modelling

Introduction

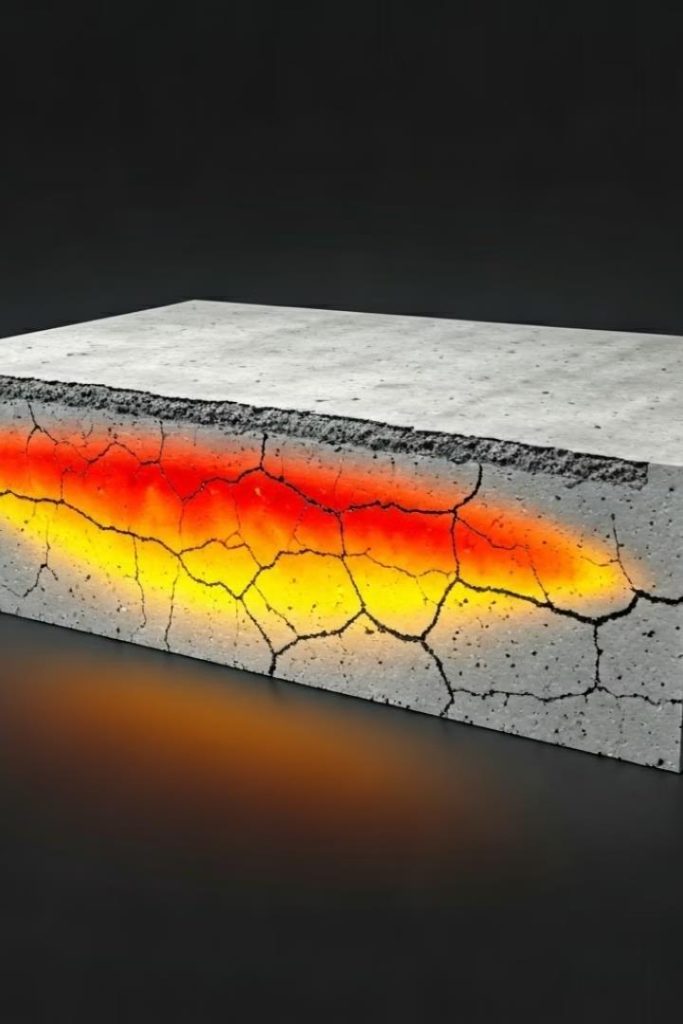

In the pursuit of more durable and sustainable concrete structures, one key factor stands out: the critical chloride threshold (Ccrit)—the concentration of chlorides that causes depassivation of steel reinforcement, initiating corrosion.

In 2022, the international working party fib TG 8.9.3 was formed to better define and apply Ccrit distributions in durability modelling. The aim: improve service life prediction tools and overcome the limitations of traditional “deemed-to-satisfy” (DtS) provisions found in most national codes.

What Is Ccrit—and Why Does It Matter?

Ccrit refers to the chloride concentration at which reinforcement in concrete begins to corrode. But it’s not a fixed value. It can vary significantly based on:

- Type of steel (e.g. carbon, stainless, galvanised)

- Concrete composition and quality

- Environmental conditions

- Testing and measurement method

The fib TG 8.9.3 working party, led by Frank Papworth, is developing a more accurate way to model and apply this critical variable using probabilistic distributions.

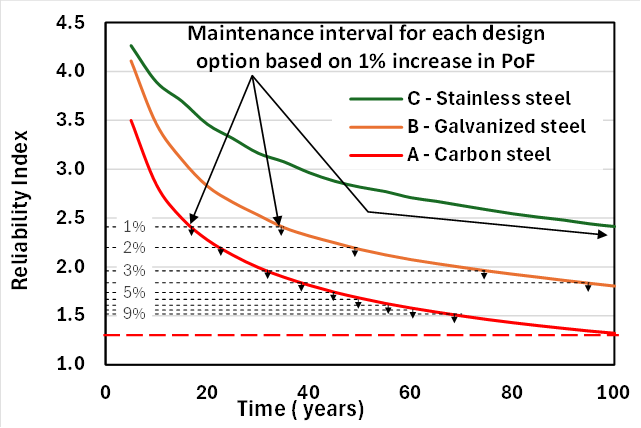

Beyond Deemed-to-Satisfy Rules

Most design standards offer DtS provisions—conservative rules designed to ensure safety under worst-case scenarios. However, they often:

- Over-design structures, wasting materials and cost

- Underperform in aggressive chloride environments

- Fail to account for site-specific variables

Probabilistic modelling provides flexibility, enabling engineers to optimise designs with real-world variables.

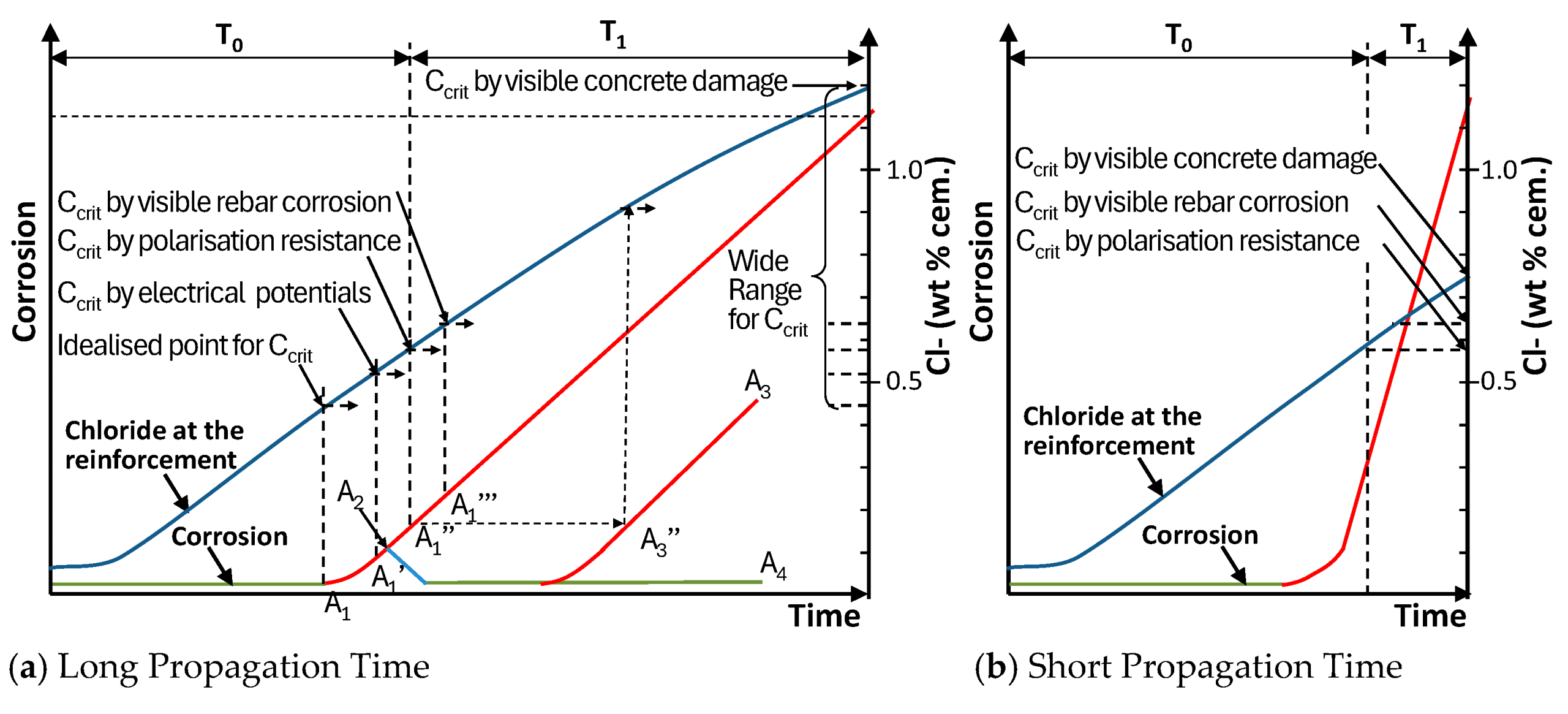

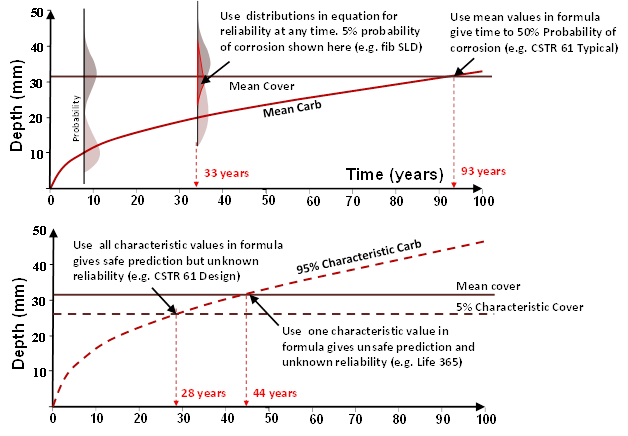

Understanding the Variability in Ccrit

Ccrit measurement is highly variable. Different methods yield different results. Electrochemical tests detect early corrosion, while visual inspections detect it much later. Field variability adds to this complexity.

Ccrit Measurement Methods and Their Impact

BCRC’s Frank Papworth is the lead author of a recent technical paper from the fib TG 8.9.3 working group, which focuses on better defining the chloride concentration that depassivates reinforcement (Ccrit). This is a crucial parameter when modelling the service life of both new and existing reinforced concrete structures.

A key insight from the paper highlights how different methods used to measure Ccrit can yield significantly different values—a finding with major implications for durability design and life prediction models. The work aims to improve the consistency and reliability of Ccrit distributions for practical use in service life modelling.

An interesting aspect of the paper is the understanding of how different approaches to measuring Ccrit can yield significantly different values, as illustrated in the figure below.