Effective Thermal Management in Precast Concrete for Major Infrastructure Projects

The Victoria Park-Canning Level Crossing Removal (LXR) Project is part of the Metronet infrastructure initiative. The project is Perth’s first major elevated rail designed to improve public transport safety, create new and versatile public spaces for the community, and reduce traffic congestion.

When complete, the Victoria Park-Canning Level Crossing Removal Project will feature five new, modern elevated stations, further enhancing connectivity and reducing travel disruptions across Perth. This milestone marks a significant step toward a more efficient and accessible public transport network for the city.

Thermal Management Challenges

BCRC tackled one of the biggest challenges in the precast concrete industry: managing heat during curing. With over 790 precast elements, including piers, Roofs, L-beams, and headstocks, manufactured for the project, implementing effective thermal management strategies was essential to maintaining structural integrity and meeting the tight schedule.

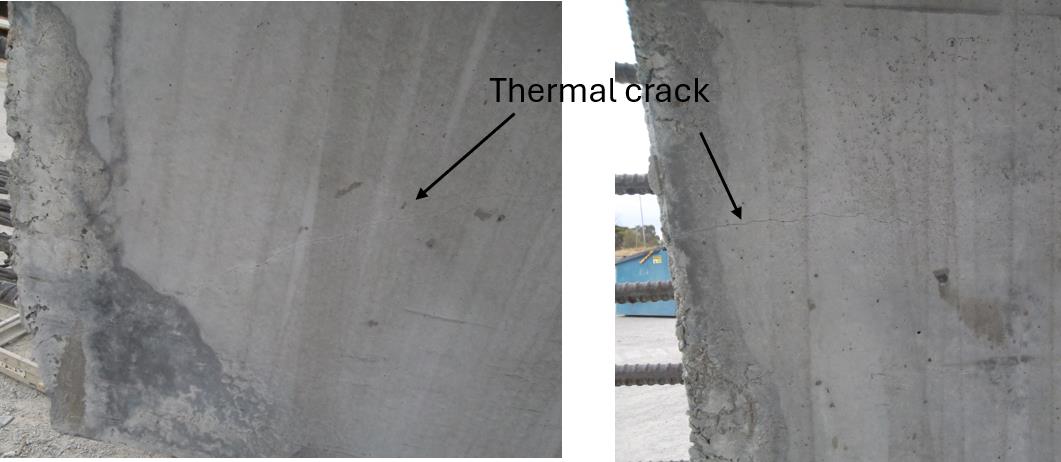

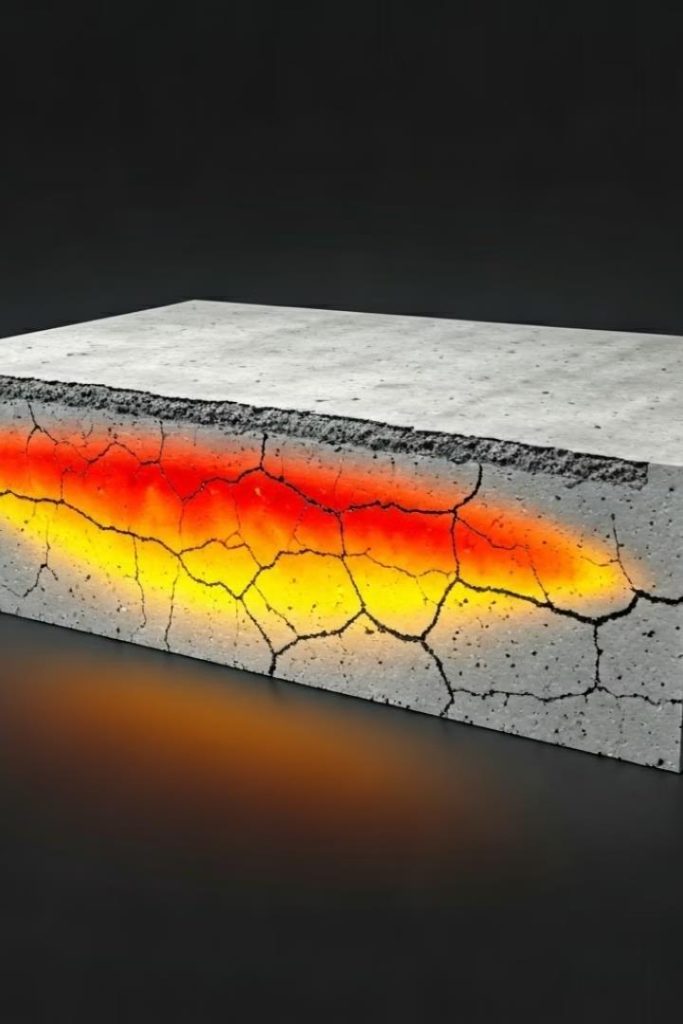

In precast concrete projects, heat of hydration, which is released during cement curing, can lead to thermal cracking and Delayed Ettringite Formation (DEF) if left unchecked. This project encountered added complexity due to the varied geometries and thicknesses of the elements, posing specific challenges:

1. High Binder Content Mixes:

These mixes were essential to achieve the rapid strength gains required but also significantly increased the internal heat, complicating temperature control.

2. Complex Geometries:

The varying thicknesses across different sections of the precast elements led to uneven heat distribution, making it difficult to ensure uniform cooling.

3. Accelerated Curing Requirements:

The project’s ambitious timeline necessitated fast curing, which amplified thermal control issues.

4. Maturity Considerations:

Different parts of each element cured at different rates, demanding close monitoring to avoid defects and inconsistencies.

Developing an Effective Thermal Control Plan

To overcome these challenges, the project team devised a comprehensive thermal control plan incorporating several key strategies:

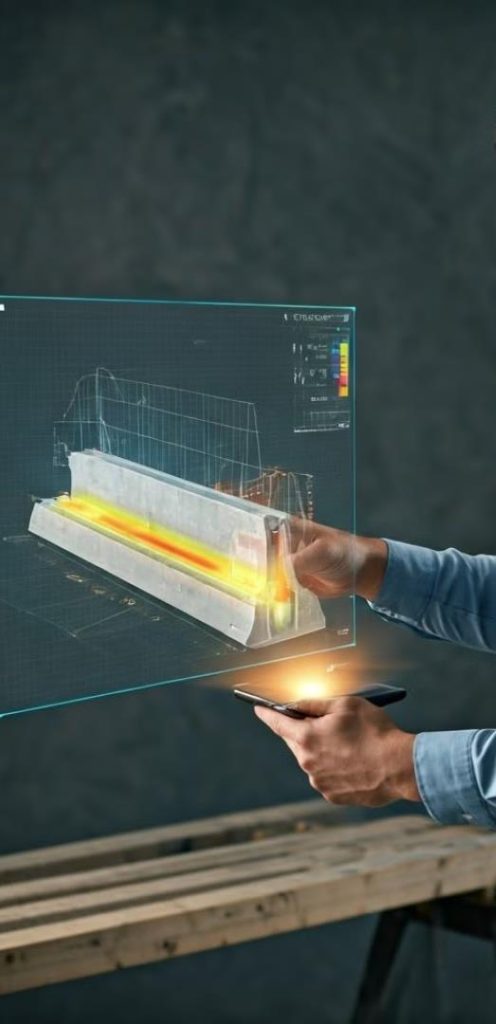

• FEM-Based Thermal Modelling:

This advanced modelling provided detailed insights into heat flow patterns, identifying hotspots and enabling targeted cooling interventions.

• Cooling Pipe System:

Embedded cooling pipes were strategically placed to dissipate heat in critical areas. Adjusting the pipes’ size, spacing, and flow rates allowed for consistent cooling across the elements.

• Optimized Steam Curing:

The team carefully adjusted the steam curing process to align with the natural heat of hydration, promoting uniform maturation.

• Real-Time Monitoring and Validation: Thermocouples embedded in the elements facilitated continuous temperature monitoring. This real-time data allowed for dynamic adjustments to the cooling system, ensuring effective thermal management.

Results and Key Takeaways

The thermal management strategies implemented on this project resulted in several notable outcomes:

• Minimal Cracking: Almost no significant thermal cracking was observed in the precast elements, demonstrating the effectiveness of the cooling and monitoring systems.

• Accelerated Construction: The ability to strip formwork in hours rather than weeks greatly streamlined the construction process.

• Specification Compliance: Temperature differentials were kept below the project’s stringent limits (70°C peak temperature and 20°C differential), confirming the project’s success in thermal management.

Key Takeaways for Future Projects

This case study offers important insights into the significance of effective thermal management in complex precast concrete projects:

1. FEM Modelling is Essential: Multi-dimensional thermal analysis allows for accurate predictions of peak temperatures and temperature gradients, particularly in complex structures.

2. Cooling Systems Are Crucial: A well-designed cooling system is indispensable for managing internal heat and preventing thermal cracking.

3. Continuous Temperature Monitoring: Real-time data enables immediate adjustments, ensuring consistent thermal control throughout the curing process.

4. Early Expert Engagement: Engaging thermal management experts early in the design phase can help pre-empt potential issues and streamline project execution.