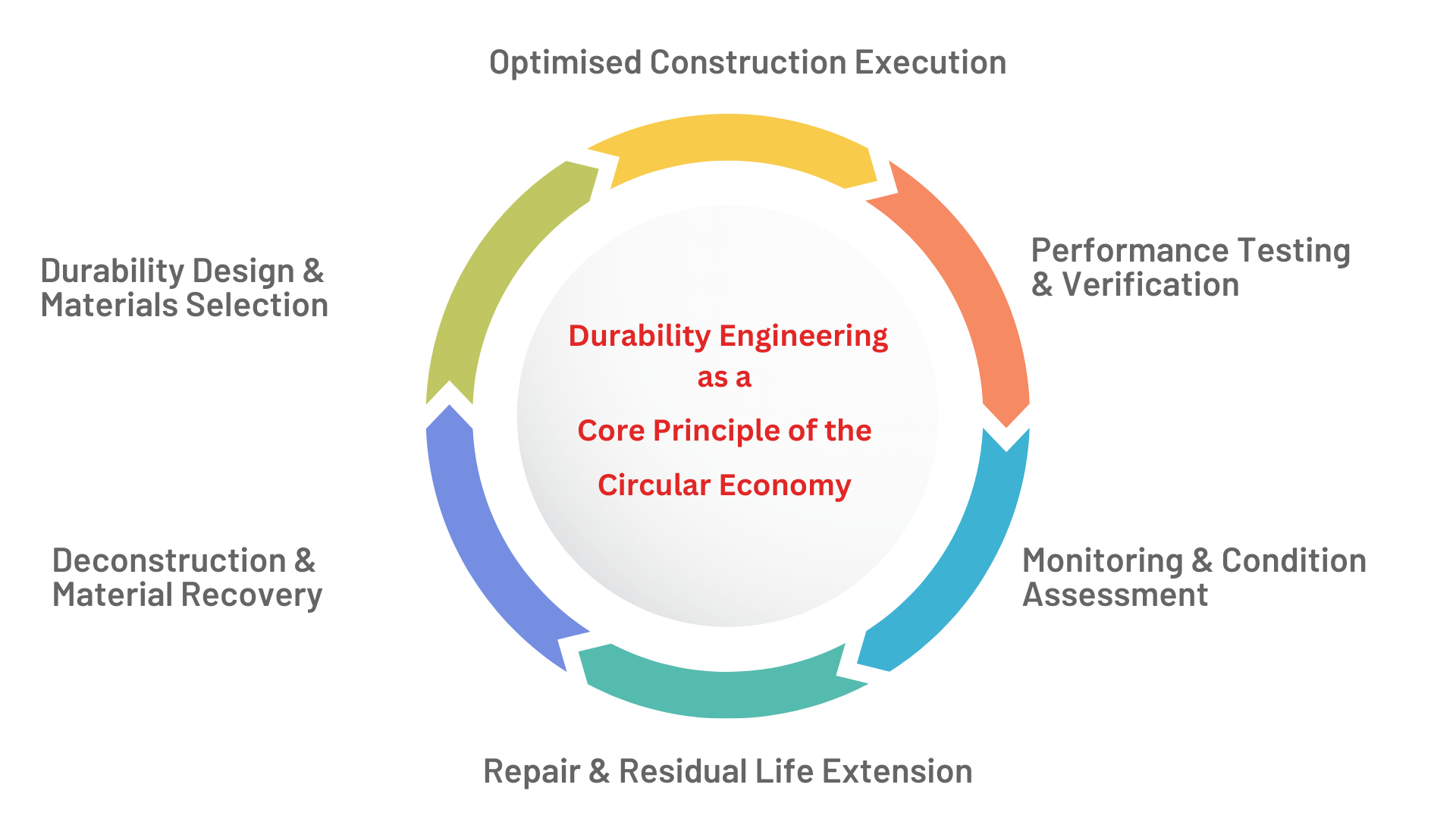

At BCRC, we pride ourselves on leading from the front—whether it’s designing for durability, conducting structural inspections, or delivering best-practice repair advice. Our work is underpinned by deep technical knowledge and a commitment to staying at the forefront of global developments in concrete technology.

That commitment was recently on display when Dr Jessie Ratcliffe, who leads our Victorian team and holds a PhD in Materials Engineering, travelled to Europe to participate in two major industry events.

International Conference on Concrete Repair, Durability and Technology

Concrete Solutions 2025 | Lisbon, Portugal | 16–18 June 2025

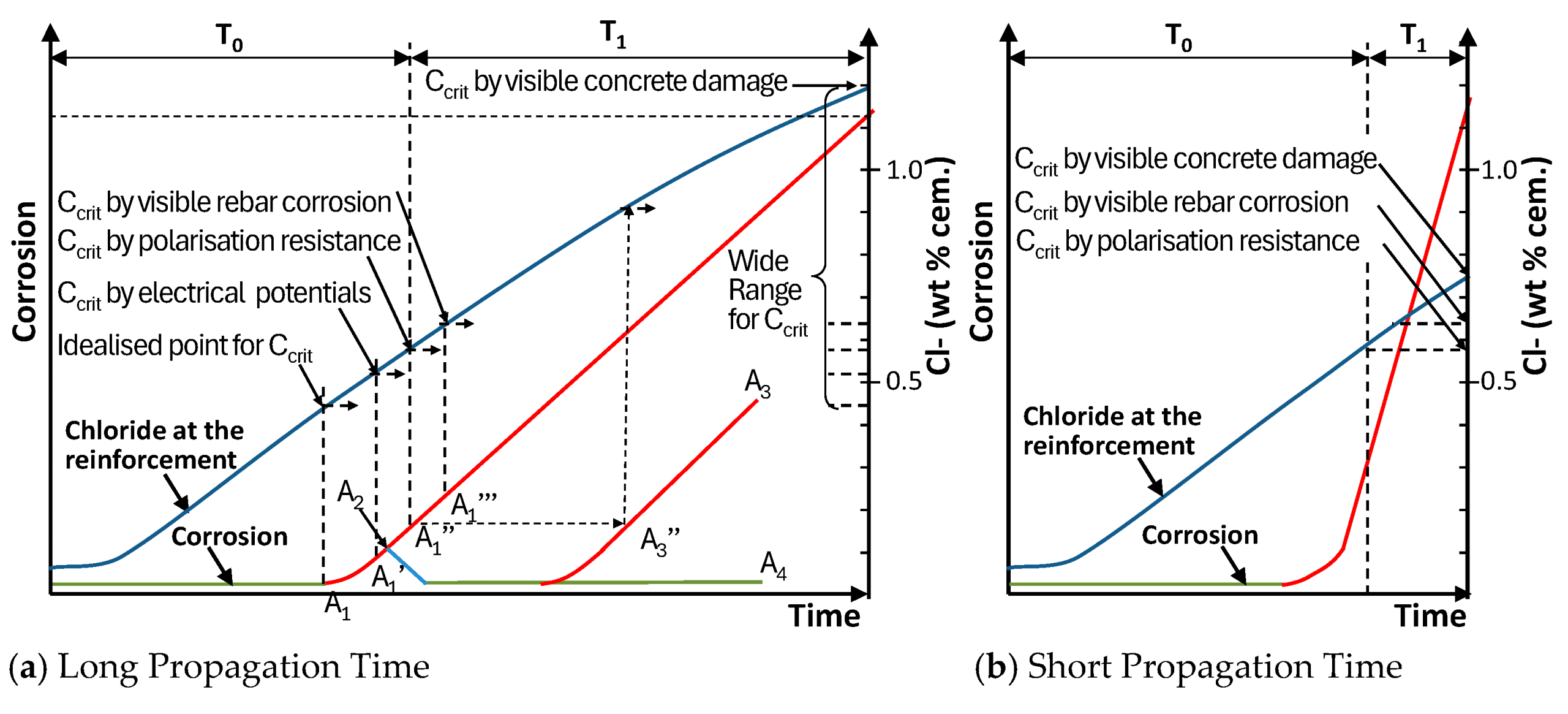

Dr Ratcliffe attended the 9th International Conference on Concrete Repair, Durability and Technology, hosted by LNEC in Lisbon. This leading global event brought together engineers, researchers and asset owners from around the world to share the latest in research, product development and field applications across:

- Concrete durability and admixture technology

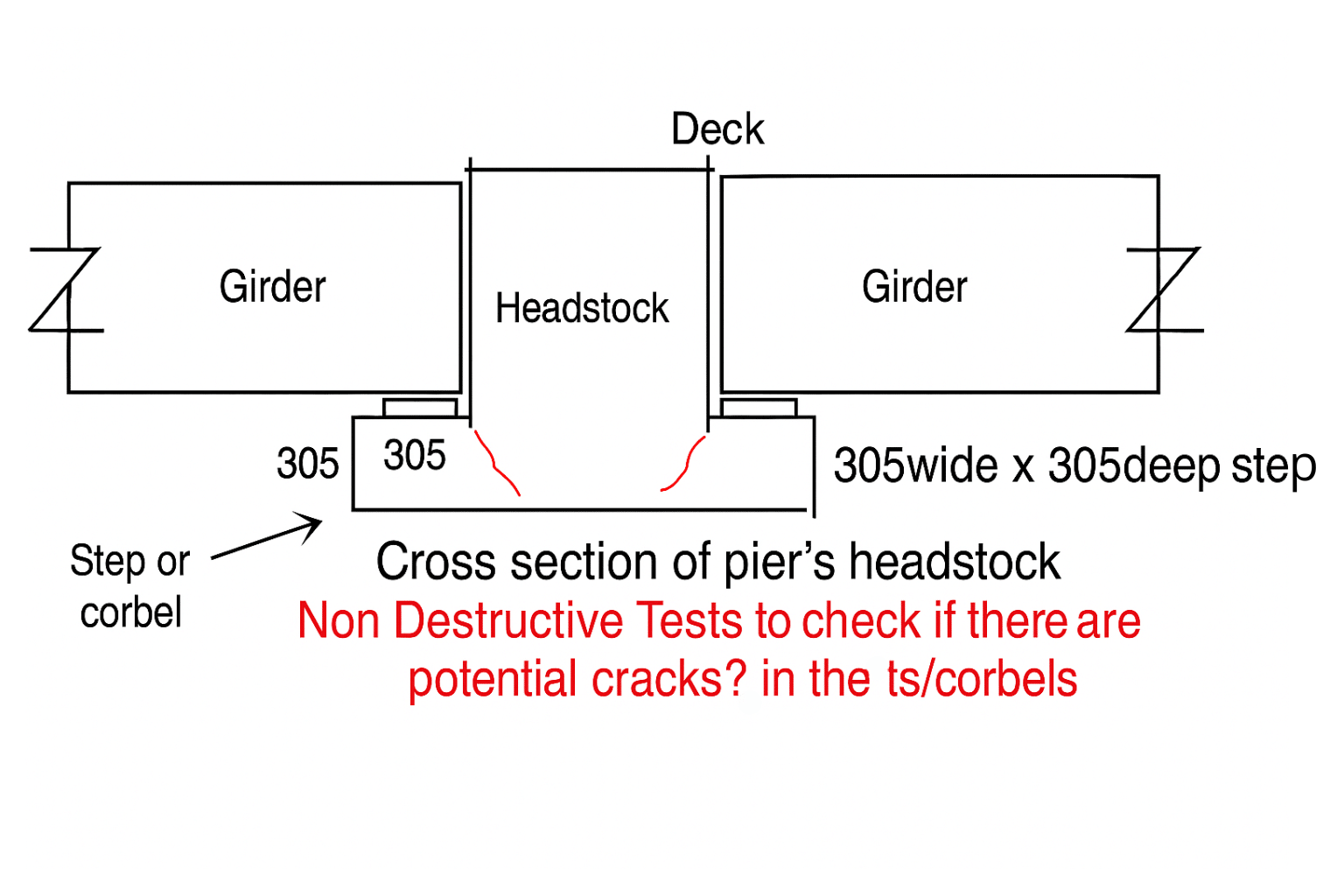

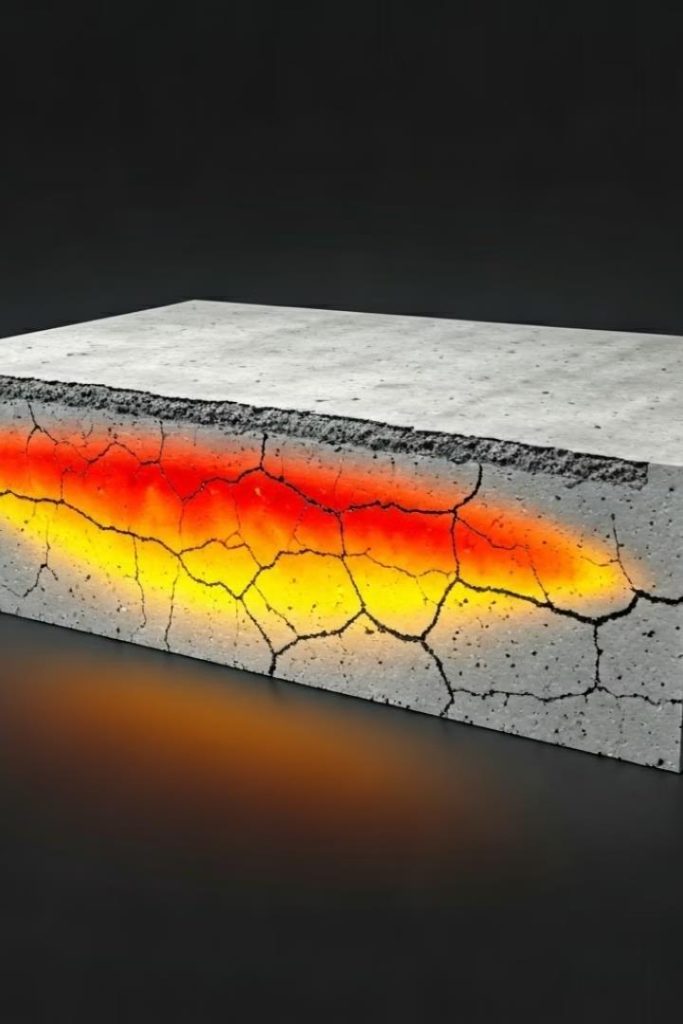

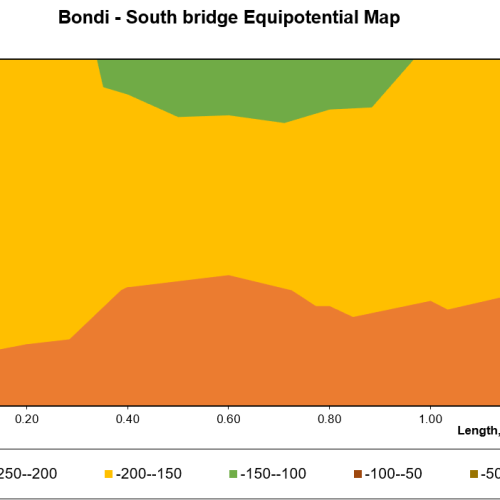

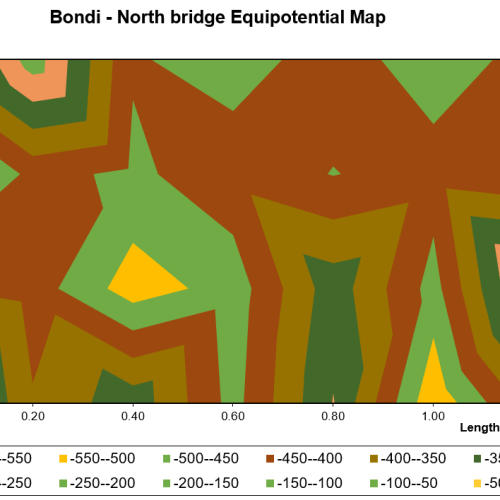

- Electrochemical repair and NDT diagnostics

- Repair of fire-damaged structures and heritage conservation

- Structural health monitoring and surface protection

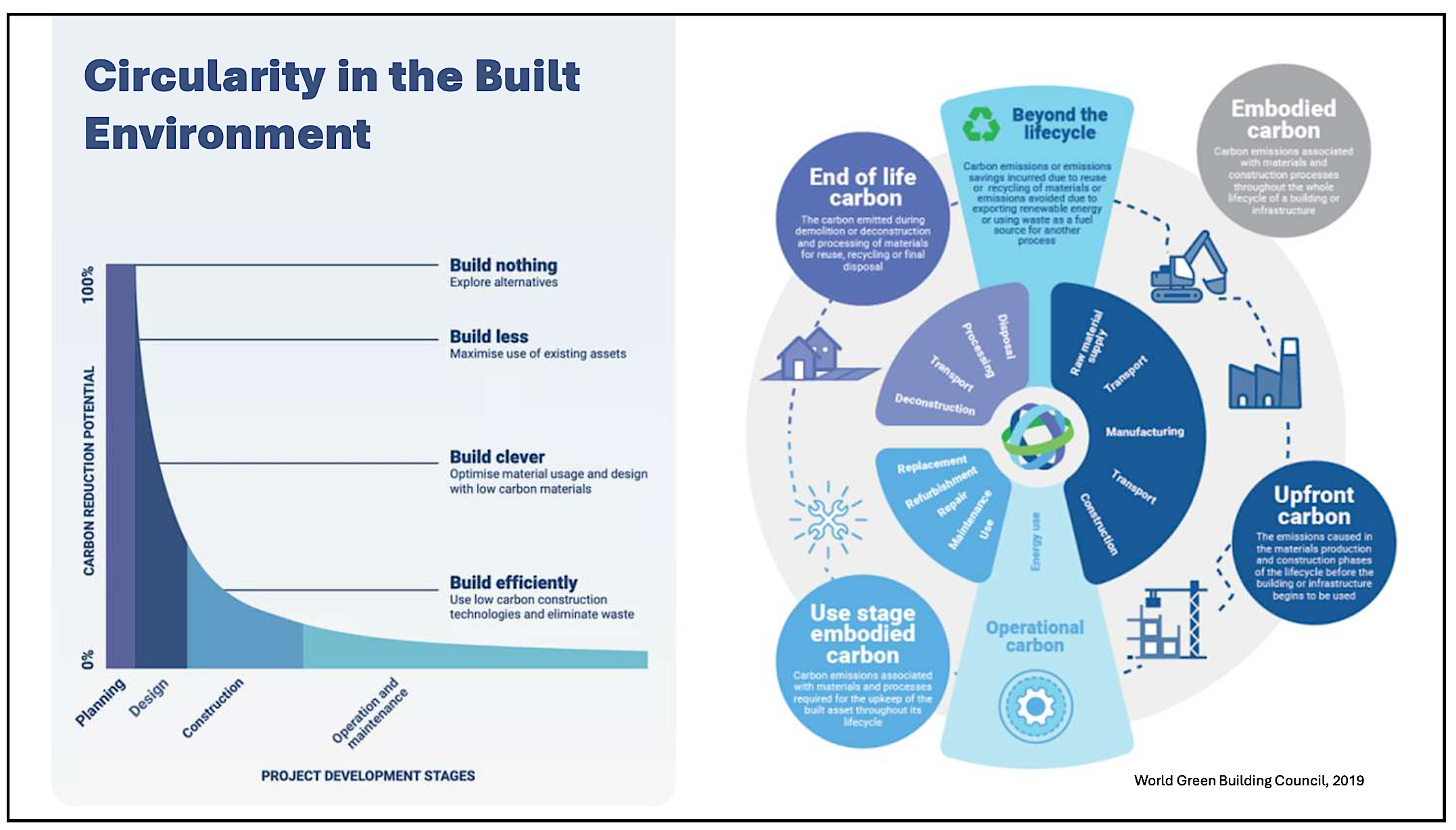

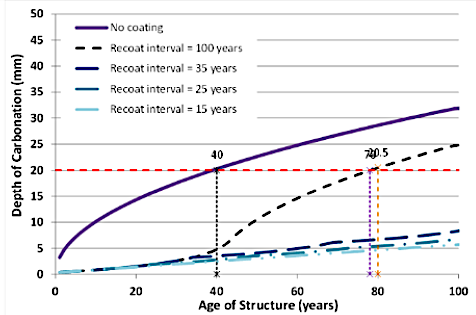

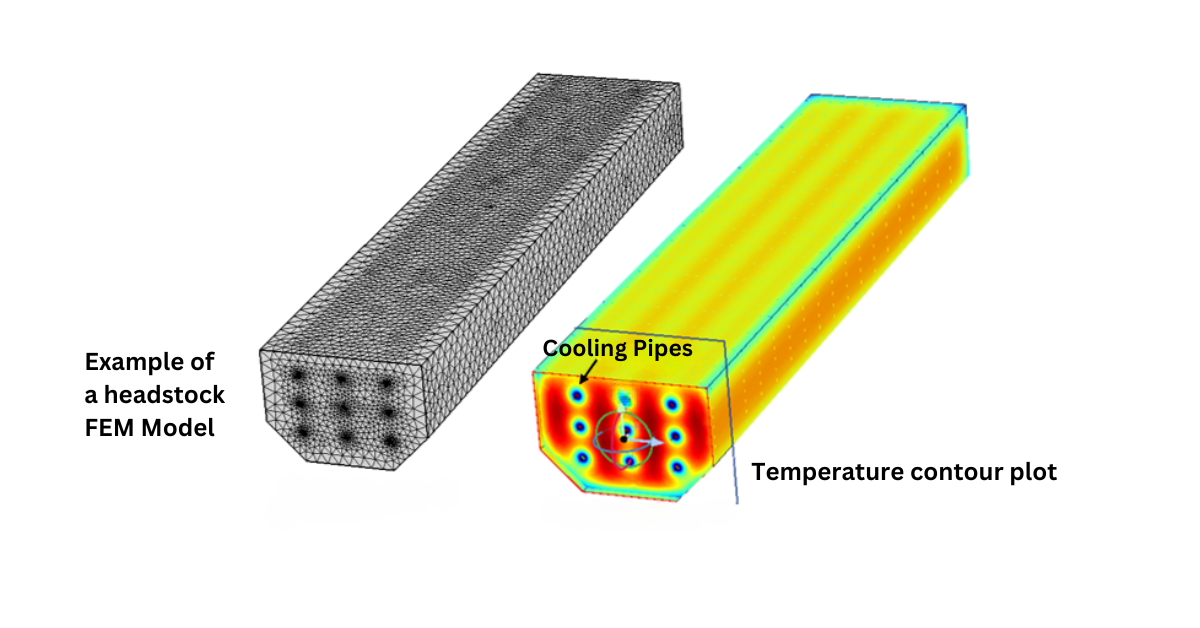

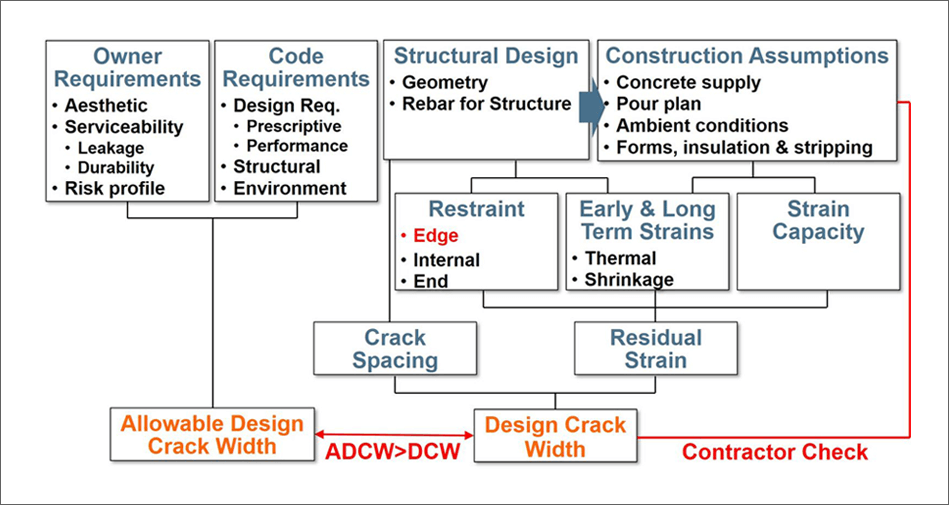

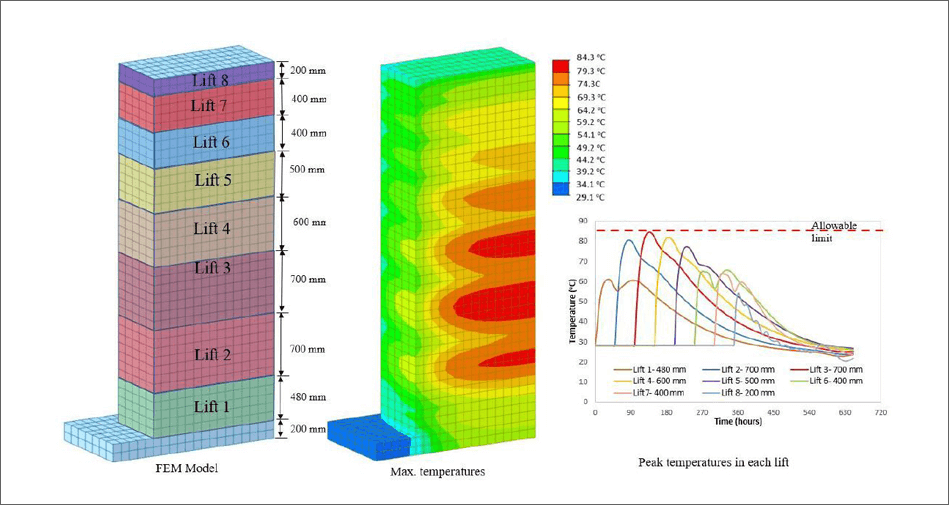

- Sustainable repair technologies and service life modelling

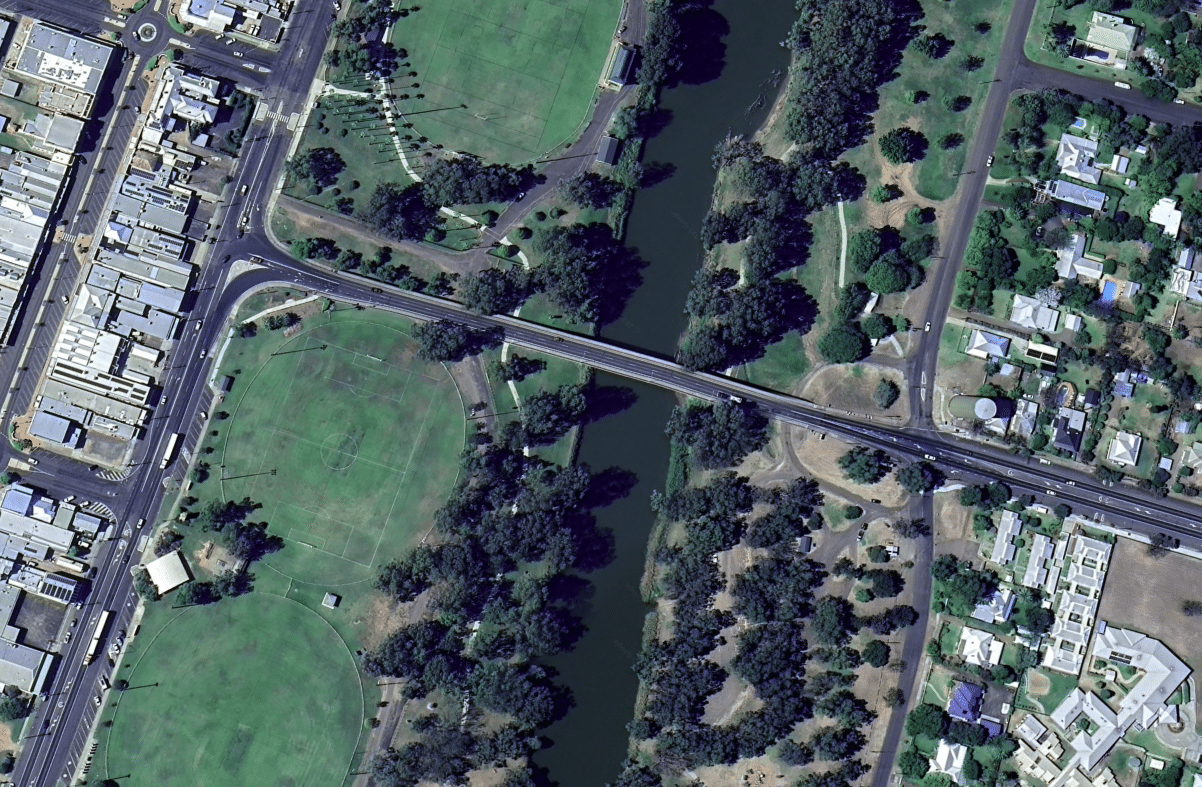

The event provided a valuable opportunity to explore cutting-edge techniques for extending the service life of infrastructure, central to BCRC’s mission of helping clients reduce lifecycle costs through better design and maintenance.

During the conference, Dr Ratcliffe also caught up with industry colleagues, including Nick Critchley from Marine & Civil Maintenance, whose team specialises in repairs and chloride extraction. Collaborations like these strengthen our ability to deliver real-world, results-focused solutions.

Advanced Training in Non-Destructive Testing and Evaluation

NDT6E-CE Course | Berlin, Germany | 25 June – 1 July 2025

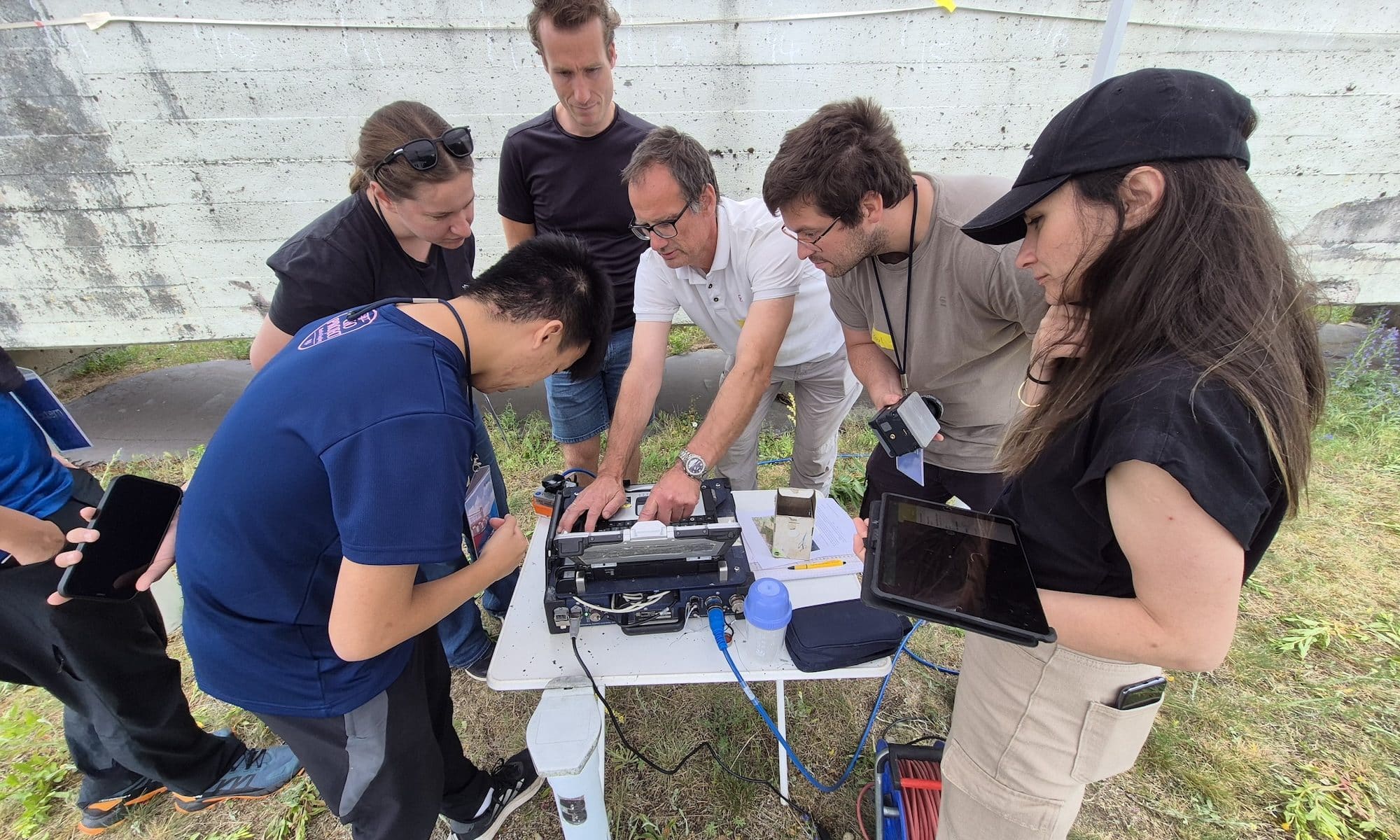

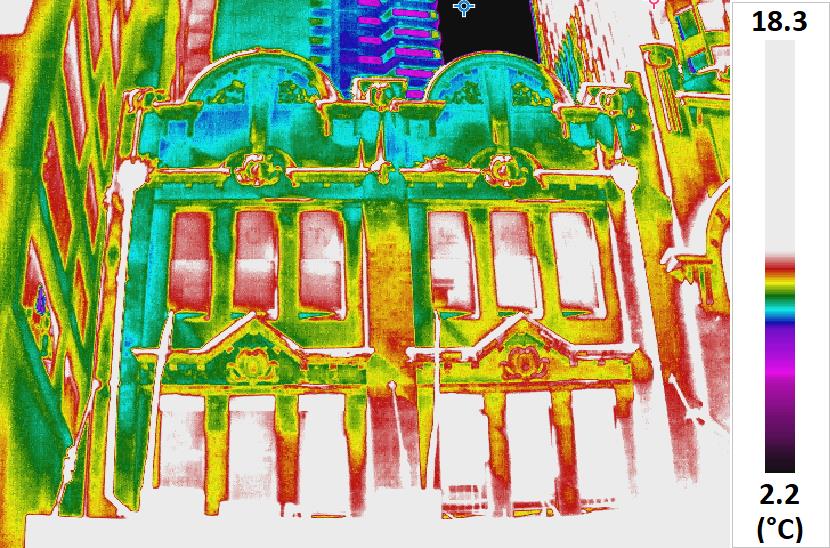

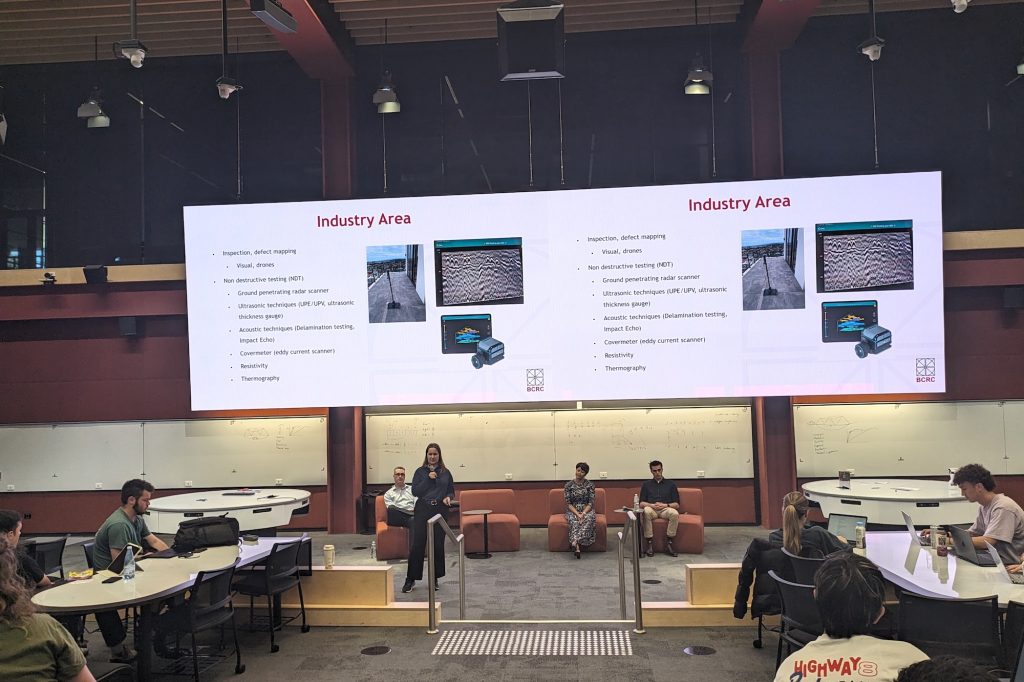

Following the conference, Dr Ratcliffe attended the Non-destructive Testing and Evaluation in Civil Engineering course at BAM—the Federal Institute for Materials Research and Testing in Berlin.

The intensive five-day program provided hands-on experience with state-of-the-art NDT equipment and techniques used to evaluate the condition of civil structures. Dr Ratcliffe is the third person at BCRC to have completed BAM training.

This training reinforces BCRC’s leadership in the use of NDT to assess concrete performance, structural health and long-term durability—crucial for managing ageing infrastructure with minimal disruption and maximum precision.

Engineering Expertise Meets Global Innovation

BCRC continues to invest in the professional development of our team and maintains close links with global leaders in research and practice. Whether we’re applying advanced diagnostics or designing for 100-year performance, we bring the latest thinking to every project.

For expert advice on durability and structural assessment, contact BCRC Durability Consultants today.