Ensuring Structural Integrity: Narrabri Bridge Inspection Project

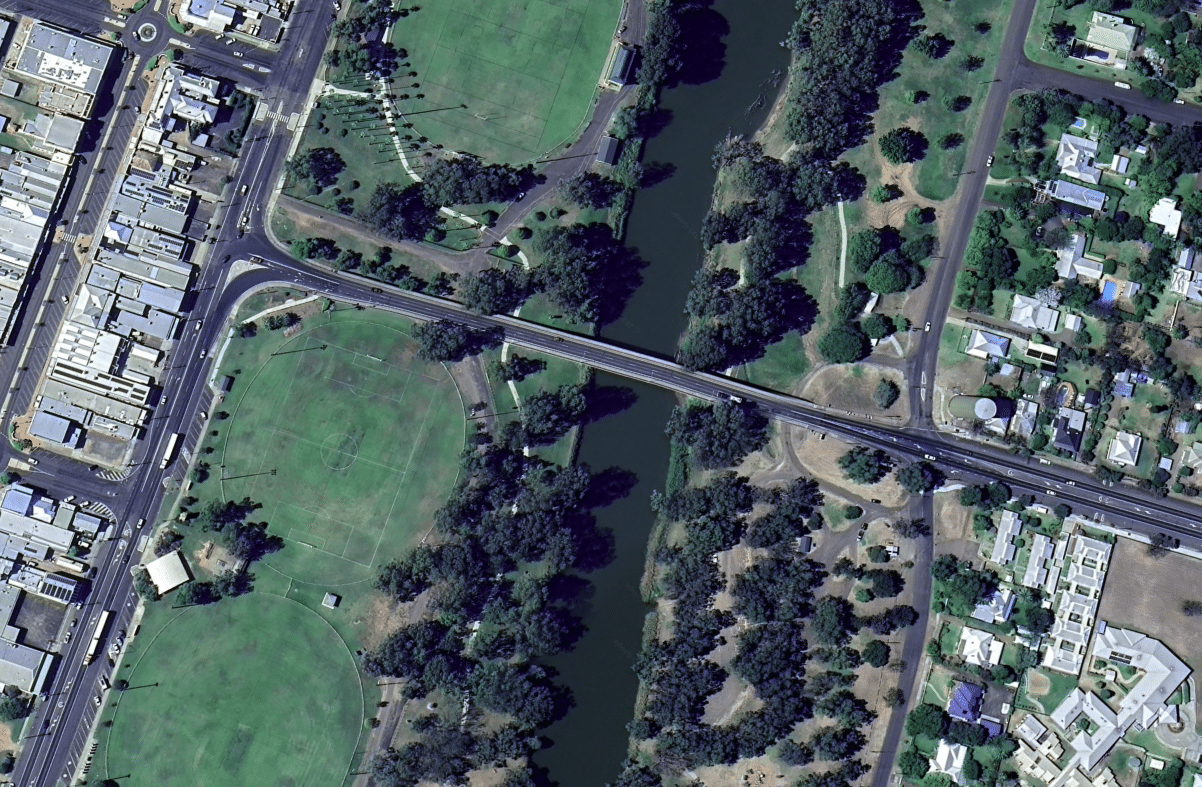

Bridges form a vital part of our transport network, and maintaining their structural health is crucial for public safety and infrastructure longevity. BCRC Durability Consultants recently conducted an extensive inspection on the Narrabri Bridge, located on the Newell Highway (HW17) in Narrabri, NSW, at the request of Transport for NSW (TfNSW).

Here’s an insight into the project, its findings, and recommended actions.

Project Overview – Narribri Bridge

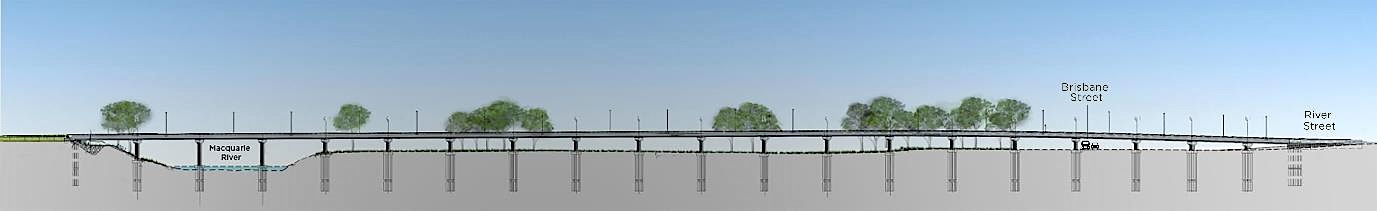

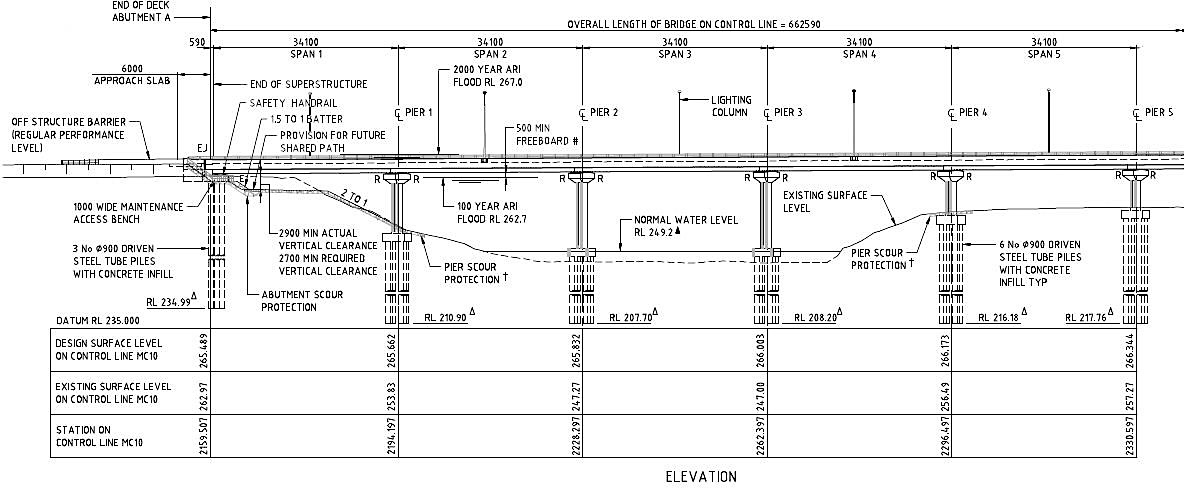

The Narrabri Bridge comprises multiple sections constructed at different times, with our investigation focused on the western end completed in 1977. Now 47 years old, this reinforced concrete beam bridge spans Narrabri Creek, supported by prestressed girders on eight piers.

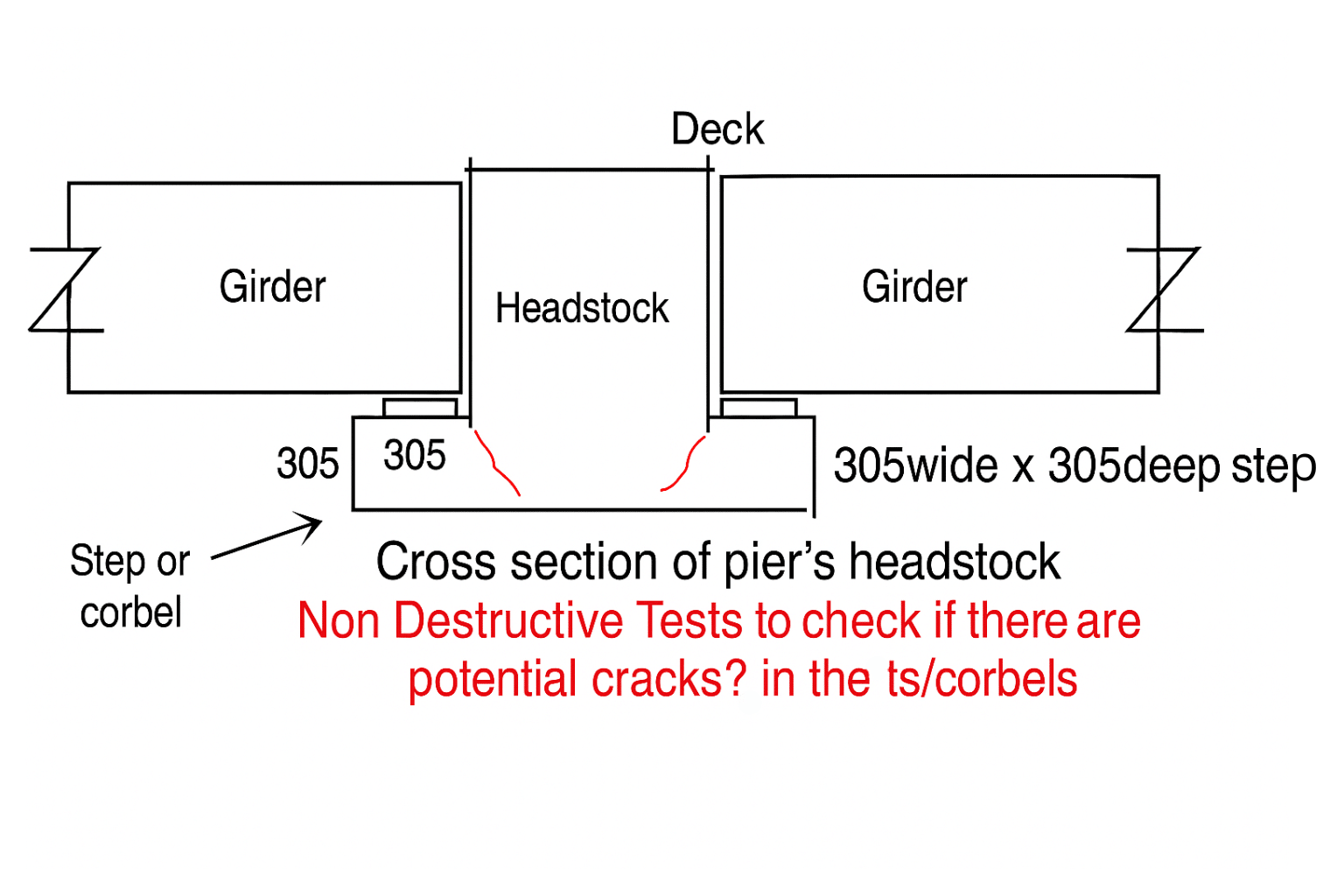

BCRC’s inspections targeted 4No. piers, utilising advanced non-destructive testing (NDT) techniques to identify potential defects without causing harm to the structure.

Advanced Inspection Techniques

To ensure a thorough understanding of the bridge’s condition, our team employed multiple NDT methods, including:

- Ground-Penetrating Radar (GPR): To detect reinforcement positions and internal

- Ultrasonic Pulse Echo (UPE) and Ultrasonic Pulse Velocity (UPV): To identify voids and cracks and assess concrete quality.

- Impact Echo (IE): To detect flaws or defects within the

- Rebound Hammer Testing: To evaluate surface hardness and estimate compressive

Structural Assessment Summary and Remediation Plan

The detailed structural investigation of 3No. Piers confirmed their excellent condition, with no significant internal defects or signs of concrete deterioration. These piers demonstrate reliable material performance and structural soundness, affirming the effectiveness of the original construction.

Targeted Remediation Strategy for the Fourth Pier Based on Advanced Diagnostic Techniques

The fourth pier was subject to a comprehensive assessment utilising both visual inspections and advanced non-destructive testing (NDT) methodologies. This integrated investigative approach proved highly effective in guiding a focused and informed remediation plan:

- Surface Condition Assessment and Treatment

Visual inspections identified surface-level changes at the headstock and corbel faces, which provided early indicators for stress-related behaviour. These observations allowed for the timely application of specialised crack sealing techniques, effectively mitigating any risk of moisture ingress and maintaining the element’s long-term durability. - Advanced Internal Diagnostics and Restoration

NDT methods—including Ultrasonic Pulse Echo (UPE) and Impact Echo (IE)—were instrumental in detecting subtle internal variations near the girder connection zones. These findings informed the decision to conduct targeted core sampling, which validated the presence of isolated voids. As a result, precision pressure grouting (void injection) is being applied to restore internal continuity and enhance structural soundness. - Material Performance Profiling and Strength Optimisation

The core extraction process not only validated internal observations but also provided valuable compressive strength data. This enabled a tailored strength enhancement strategy, ensuring the pier’s capacity is brought in line with adjacent structures. The findings also support refinement of design assumptions for future asset maintenance and upgrades.

Proactive Structural Health Monitoring

Based on the detailed diagnostic outcomes, a long-term monitoring regime has been established. This includes scheduled inspections, condition tracking, and trend analysis, allowing for proactive maintenance and adaptive management of the pier’s condition over time.

Monitoring Structural Integrity for the Narribri Bridge

Through our comprehensive inspections and detailed analysis, we aim to help Transport for NSW ensure the continued safety and durability of the Narrabri Bridge. Regular monitoring, timely interventions, and advanced NDT methods will play critical roles in maintaining the structure’s longevity.

Get in touch with the BCRC team to learn more about bridge durability solutions or discuss similar projects.