Bondi Beach Park Remedial Work

BCRC Bondi Beach Park Remedial Work

Since the mid-1800s, Bondi Beach has been a cherished destination for families, picnics, and beachgoers, evolving into a cultural landmark over the decades. The beach’s popularity soared with the advent of the first tramway in 1884, the construction of surf bathing sheds in 1903, and the opening of the Bondi Pavilion in 1929, which drew a staggering crowd of 200,000. The pavilion, renovated in 2022 by Tonkin Zulaikha Greer Architects (TZG), symbolizes Bondi’s vibrant heritage and enduring charm.

BCRC was engaged to provide inspection services for the concrete elements of the pedestrian bridge and walkway structure leading to Bondi Park and the beachfront.

This article highlights the scope of work and advanced techniques BCRC employs to safeguard this iconic structure.

Comprehensive Inspection and Testing: The BCRC Approach for Bondi Beach

The BCRC team conducted rigorous field and laboratory investigations, utilizing advanced methodologies and tools to evaluate and enhance the durability of the concrete structures.

Visual Inspection and Drummy Survey

Using their proprietary SMART Inspect methodology, BCRC performed thorough visual inspections to identify spalling, cracks, corrosion, and other risks. The Drummy survey, conducted in accordance with ASTM D 4580 standards, identified delaminated areas of concrete that were not visible to the naked eye.

Rebound Hammer Test

The rebound hammer test was employed to assess the concrete’s compressive strength and surface hardness. This non-destructive test provided critical data on the structural durability, guiding further assessments.

Cover Survey Test

BCRC conducted a detailed cover survey to verify the adequacy of the concrete cover over reinforcement bars. This test ensured that the concrete cover met design specifications, a crucial factor in protecting against environmental exposure and corrosion.

Core Sampling

Core samples were extracted to analyze compressive strength and durability characteristics. Key assessments included:

1. Over Reinforcement Coring: This revealed rebar dimensions and allowed visual inspection of reinforcement conditions.

2. Durability Testing: To estimate the remaining service life, chloride and sulfate ion content, as well as carbonation depth, were evaluated.

3. Petrographic Analysis: Concrete quality was assessed, identifying potential alkali-aggregate reactions and other durability factors.

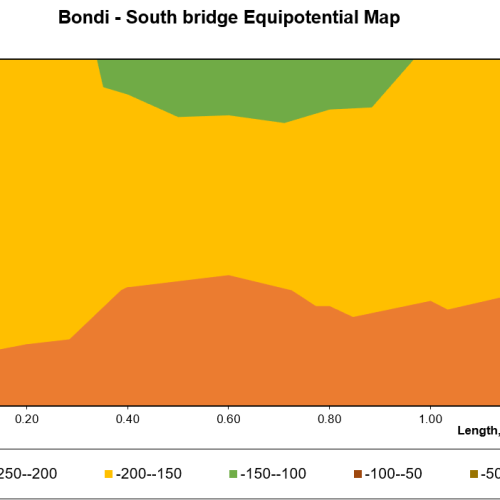

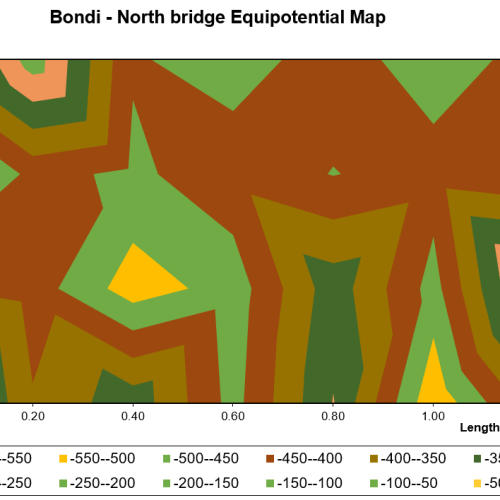

4. Half-Cell Potential (HCP) Survey

BCRC utilized the Proceq Profometer to measure the likelihood of reinforcement corrosion. By analyzing HCP data beyond standard guidelines, the team delivered precise corrosion risk assessments tailored to the structure’s specific conditions.

Data-Driven Solutions and Advanced Reporting

The investigations culminated in a comprehensive report that included:

- Detailed observations with photographic evidence.

- Compressive strength calculations.

- Analysis of degradation rates.

- Remaining service life estimations using proprietary and industry-standard models.

-

This report provided actionable insights and recommendations for the future maintenance and preservation of the structures.

Tailored Repair Specifications for Longevity

BCRC’s EPIC Repair system was employed to identify the most suitable repair methods. These ranged from localized patch repairs to advanced cathodic protection systems, ensuring all repairs aligned with long-term performance goals.