Cooling Pipe Systems for Concrete in Infrastructure Projects

Innovative Cooling Pipe Systems for Concrete in Major Infrastructure Projects

BCRC, a leader in construction technology, has pioneered advanced cooling pipe systems to tackle the complex challenges of managing concrete’s heat of hydration and mitigating thermal cracking in key transport infrastructure projects.

Cooling Pipe Systems: An Efficient, Cost-Effective Solution

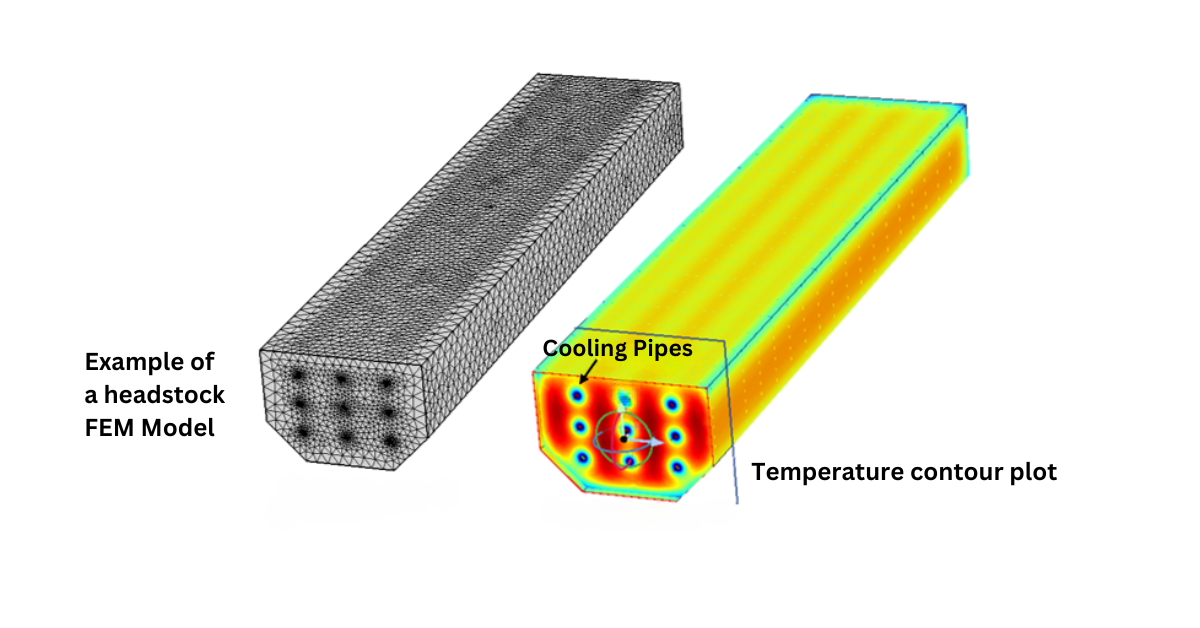

In Australia’s challenging climate, controlling concrete placement temperatures is a persistent challenge for the construction industry. However, BCRC’s post-cooling techniques offer an efficient and cost-effective solution. By embedding cooling pipes within the concrete structure, circulating water absorbs the heat generated during hydration, effectively regulating temperatures and preventing thermal damage.

Innovation Meets NSW Government B80 Specifications

The cooling system, designed by BCRC’s Technical Director, Dr. Inam Khan, was successfully implemented in the Newell Highway Upgrade – New Dubbo Bridge project. Collaborating with Abergeldie Complex Infrastructure, BCRC developed customized cooling systems for critical bridge elements. These systems met Transport for NSW’s rigorous B80 specifications, achieving a peak temperature cap of 70°C and a temperature differential limit of 20°C. This cooling approach met thermal requirements and significantly reduced formwork removal times, accelerating the construction timeline.

A Major Infrastructure Project for the Region

The $263.2 million New Dubbo Bridge is making substantial progress, with a third of its concrete deck—designed to support future traffic—already in place. Jointly funded by the Australian Government, which has contributed $210.6 million, and the NSW Government, which has provided $52.6 million, this project is a vital investment in the region’s infrastructure.

BCRC’s Commitment to Concrete Durability in Harsh Environments

BCRC’s cooling systems underscore the potential for sustainable, effective solutions in modern infrastructure, setting new concrete durability and efficiency standards in Australia’s harsh environments. BCRC’s material engineers ensure that performance and workmanship requirements are rigorously defined for concrete durability. Yet, these standards can only be met if quality control in materials handling, batching, transportation, placement, compaction, finishing, and curing are strictly followed.

With expertise across the entire concrete lifecycle, BCRC offers comprehensive management to achieve fit-for-purpose, high-quality concrete that meets demanding structural needs in challenging climates.