Waterproofing Defects Assessment And Solutions

Water ingress, leaks, flooding and mould are the most common defects facing strata buildings. These are often the result of design flaws, incorrect material selection, poor quality control measures and non-compliant building practices. It’s essential that water-related issues are accurately detected and remediated at their source, to maintain an asset’s structural integrity.

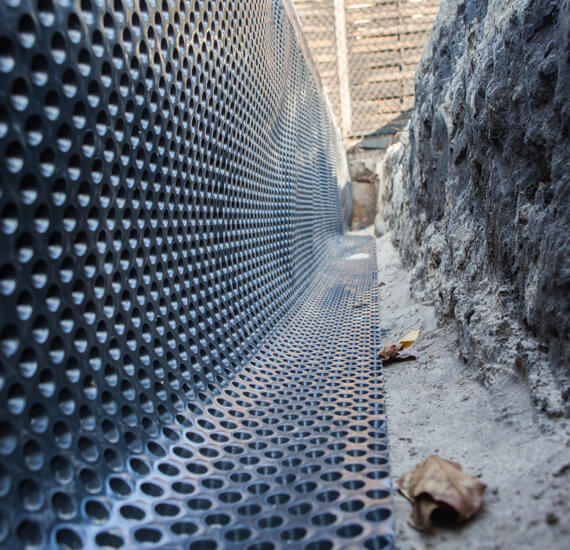

Materials and waterproofing membranes are critical to the performance of rooftops, facades, balconies, windows, bathrooms, planter boxes, pavers and basements. It’s vital to align a regulated membrane system design with the specific requirements and expected maintenance cycles of the client strata corporation.

That’s why we collaborate closely with architects, builders, material and coating manufacturers and contractors to thoroughly investigate, inspect, test and diagnose defects attributed to waterproofing issues.

Technical experts in Membrane Selection

From expert witness engagements, to inspection and testing of defective systems, BCRC recognise that waterproofing failures often stem from issues other than poor workmanship. Incompatibility of materials, inadequate design detailing, and a lack of understanding by strata corporations regarding product specifications and maintenance requirements are common pitfalls.

As specialist design practitioners, we leverage multidisciplinary expertise in all areas of design and engineering. We’re experts in all aspects of waterproof membrane systems and can assist strata owners to safeguard their properties against water damage.

When selecting a waterproof membrane system, it’s important to consider design intent, performance requirements, the building environment and the anticipated maintenance schedule, including warranties.

Our consultants regularly assess and report on failed systems and the design and oversight of new waterproof membrane system installations. We leverage our extensive knowledge of materials and technologies to consistently match the right system to our clients’ design needs that deliver long-term results.

Throughout the process of identifying and resolving building defects at their source, we ensure strict compliance with Australian Standards and the National Construction Code. This includes standards such as AS 3740, AS/NZS 4858, AS 4654.1 and AS 4654.2. These are essential benchmarks for regulated design that building practitioners rely on in the material selection and installation process.

Specialist Diagnostic Equipment And Testing Services

Water ingress presents a multifaceted risk that needs rigorous investigation in order to preserve the integrity, safety and value of a building.

BCRC offers a range of design and testing services to detect, repair and prevent major losses resulting from water penetration. Our proprietary SMART Inspect approach coupled with specialised Non-Destructive Testing (NDT) methods are used to determine the root cause of water tracking in strata buildings. We focus on the the durability of materials and the thickness of coatings and waterproof membranes.

This forensic analysis, surveying and testing methodology allows us to generate a detailed report with accurate data and evidence with respect to waterproofing compliance, future maintenance, statutory warranty, as well as insurable and uninsurable liability.

From low-cost temporary repairs or maintenance, to highly complex and innovative remedial methods, we choose the most appropriate option to extend the useful life of an asset, minimise risk and reduce costs for repairs and ongoing maintenance.

Our preferred testing method depends on the specific circumstances and the nature of the water ingress experienced by a strata building. The first step is a thorough site inspection of the potential problem areas, looking for obvious signs of water intrusion such as stains, discoloration, or warping on walls, ceilings and floors. Once complete, we can employ a range of diagnostic equipment as part of a more comprehensive investigation process.

Infrared & Thermal Imaging

This technique uses infrared cameras to detect temperature variations. Water often cools the surface it contacts, and a thermal imaging camera can help identify areas where moisture is present.

Relative Humidity Testing

Prior to installing concrete slabs, it’s critical to test moisture levels to prevent future failure of the floor coating. This is achieved via the use of a humidity probe in drilled holes within the concrete substrate.

Digital Moisture Meters

Devices that measure the moisture content of materials like wood, drywall, and concrete. They can help pinpoint areas where moisture levels are higher than normal.

Electronic Leak Detection

A testing method that uses an electric circuit through a non-conductive membrane to locate coating film discontinuities (hidden leaks) in waterproofing membranes.

Adhesion Testing

Measures the bond strength between the substrate and waterproof membrane using tensile dollies on exposed areas such as bathrooms, balconies, and rooftops.

Tracer Dyes

Dyes can be added to water, which help trace the path of a leak, which are useful for identifying the source of leaks in plumbing systems.

Dye Testing

Similar to tracer dyes, this method involves introducing a coloured dye into a system. The dye will flow with the water and exit through any leaks, making them visible.

Hydrostatic Pressure Testing

Involves applying water pressure to a system to check for leaks, and is often used for testing the integrity of structures like basements and underground tanks.

Ground Penetrating Radar (GPR)

GPR uses radar pulses to image the subsurface, detecting anomalies in the structure that may indicate the presence of water.

CCTV Inspection

In sewer and drainage systems, sending a camera down the pipes can help identify cracks, breaks, or blockages that may be causing leaks.

Ultrasonic Testing

A method using sound waves to detect the sound of water leaking, and is useful for finding leaks in pressurised systems.

Acoustic Sensors

Placed on surfaces that listen for the sound of water escaping, and can be used to detect leaks in pressurised systems.

Capacitance Sensors

Sensors detect changes in the electrical capacitance of materials, which can be indicative of moisture levels.

Speak With A Wateproofing Remedial Consultant Today

If your strata building is experiencing any type of water damage or leaks, contact BCRC for a free consultation or to schedule an inspection.