Repair design

The standard and appropriate approach to concrete and crack repair is to assess the cause of failure, extent of damage, and residual service life before finalising the repair and protection methods to be used. Incorrect diagnosis can lead to errors in repair specification that can be extremely costly. BCRC have the largest range of field concrete testing equipment in Australia and are experts in the field of deterioration. BCRC’s Durability Consultants manage durability aspects on some of Australia’s largest projects. The quality of repair will be influenced by the access system. While small repairs can be undertaken from experts suspended on ropes major repairs have to be undertaken from stable platforms. BCRC are familiar with the effect on repair quality and project time when working using different access systems.

Crack repair

Cracks in concrete are the external sign that the steel might be corroded internally. The first step is assessing whether the crack requires repair and if so to assess the condition and movement at the crack. BCRC have many corrosion and penetrability models to determine if the cracks will be detrimental to the structure. We also have a range of devices for measuring crack width and movement.

Impregnation – Cracks can be injected using polyurethanes, epoxy resins, acrylics, methacrylates, and micro-cements. The type and pressure depends on the application. BCRC have been involved in some of the most difficult crack repair projects and have developed systems for localised cathodic protection at cracks and micro cement injection to re-passivate steel at cracks.

Surface Sealing – In many instances it is wrong or unnecessary to impregnate cracks. Surface sealing may prevent the ingress of contaminants and be all that is necessary to prevent deterioration. One of the main issues is to ensure adequate movement capacity of the sealant material. Generally this means routing out the crack to provide an adequate width of repair that depends on the properties of the surface sealant. In some case the sealant may also provide a reservoir that feeds the crack to promote crystal growth at depth.

Corrosion repair

Repairs as in every field, requires to be performed by experienced well rounded professionals. A corrosion repair requires a previous inspection and assessment where recognizing the morphology of attack and corrosion mechanism is critical to avoid recurrence of the root cause. Corrosion repairs need to comply with Australian and international standards. A repair must be executed by professionals with a wide expertise in corrosion assessments and inspection and with a full understanding of the standards and the procedures applicable to any specific type of repair.

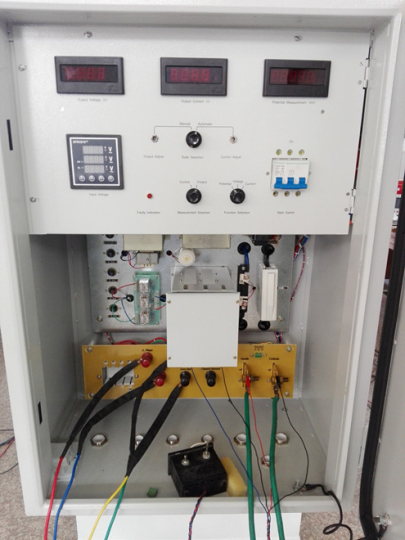

Electrochemical methods

Cathodic Protection is the main and most effective electrochemical method to protect the reinforcement in concrete and buried and submerged steel structures. CP systems can have sacrificial or current impressed anodes. BCRC has highly experienced and NACE certified CP engineers and technicians. We can provide you with designs and reviews, monitoring and maintenance programs, supervision during installation and commissioning and field testing. We are the only independent third party in WA. (to confirm with FP)

Chloride extraction was first trialed in Australia by BCRC in the 1980’s. It can be highly successful, particularly where the chlorides have not reached behind the bar.

BCRC has significant experience in the application of re-alkalisation.

Migrating corrosion inhibitors can be used for repair where the cover is low or the concrete is porus. Where concrete has spalled inhibitors can also be used in the repair concrete.

Chemical attack

Most corrosive agents are chemicals and each chemical will be more or less corrosive on a particular metal depending on a variety of factors such as concentration, pH, temperature, pressure and also the synergy with other agents in the media. There are a wide range of repair methods associated with different causes of repair. BCRC professionals are familiar with most specialist repair materials and can bring the correct system to bear.

BCRC also have experience in geopolymer concrete for acid resistance.

Heritage structures

Heritage buildings and structures are becoming assets of great importance and relevance for the modern society and governments. Aggressive environments, lack of maintenance and age can affect the integrity of these valuable assets. These structures can maintain and extend their integrity end life once an inspection plan is set and further repairs and protection methods are designed and implemented.