Applying protective coatings to different materials and surfaces is critical to defending an asset from the elements. BCRC specialise in safeguarding your structures from harsh environmental conditions. Our expert engineers and NACE-accredited coatings inspectors provide protective coatings and inspection services that reduce long-term maintenance costs, prevent premature failure and extend the service life of an asset.

We service an extensive range of structures including strata complexes, commercial buildings, basements, storage tanks, tunnels, bridges, wharves and jetties. Our technicians thoroughly inspect and assess the condition of all structures in all environments, ensuring the protective coatings used are fit-for-purpose and compliant with Australian and international specifications and standards.

Coating Inspections that prevent Costly Failures

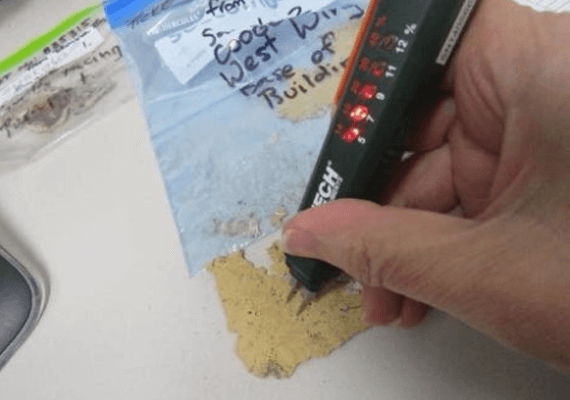

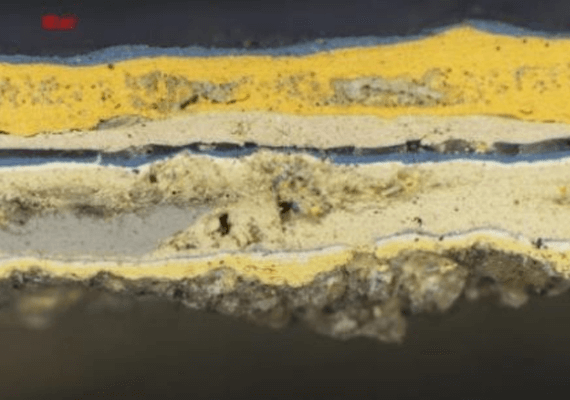

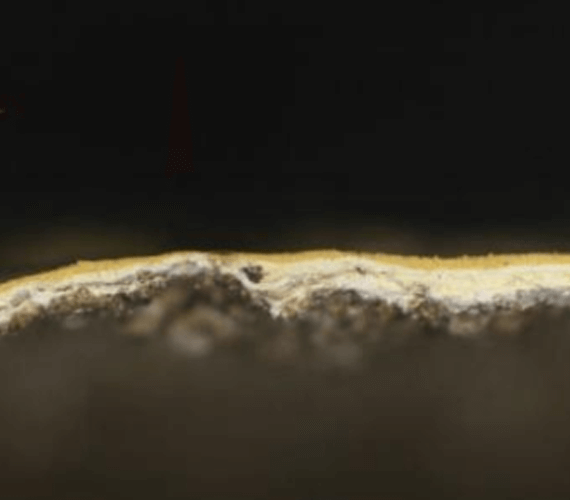

A poorly applied coating can result in downtime and expensive repairs, so early identification of potential issues will help to avoid further deterioration. From corrosion control and concrete inspections to coatings identification and failure analysis, our team ensure the right coating is applied to an asset to maximise its structural integrity and durability over the long-term.

We’re equipped with the latest tools to consult on all issues related to protective coatings and corrosion management. We conduct periodic inspections for multiple assets, from monitoring coatings performance to structural assessments that identify signs of corrosion.

Tailored Coatings Solutions

We understand that the integrity of protective coatings is critical to the longevity of an asset. From initial surface preparation and coating application to final inspection and testing, BCRC’s coatings specialists offer customised solutions to address unique project requirements. Whether it’s protecting steel or concrete structures, timber or masonry, we’ll deliver the right solutions, both above and below ground. We service everything from residential and commercial offices, mines, oil and gas operations, industrial facilities, to marine structures and government utilities.

We inspect coatings of all types, from epoxy, polymer and polyurethane, to shot blast and hot-dip galvanising systems. Our inspectors utilise non-destructive testing methods, steel corrosion and concrete condition assessments to detect issues within different structures and provide a detailed report. These include surface preparation and coating inspections, thickness measurements, high-and-low voltage testing and adhesion testing where required, to determine the integrity of the coating systems used and remedial actions required.