Magnesite-related defects such as steel corrosion and concrete spalling pose a significant risk to a building’s structural integrity.

Commonly used in thousands of apartments as a floor topping or levelling product up until the mid-1970s, magnesite-related defects pose an invasive and expensive risk if undetected or neglected.

Excessive moisture in magnesite occurs as a result of window and door leaks, bathroom waterproofing issues, water heater failures and flooding events, and humid coastal environments. The chlorides dissolve and leach into the underlying concrete, and in the wettest areas, expansive corrosion of the reinforcing steel causes concrete spalling. Neglecting it will require structural strengthening, further increasing remedial costs and in worst cases, the partial collapse of floors.

BCRC offers best-practice remedial management solutions. Beyond simply preparing remedial works specifications, we oversee projects, from contractor selection and administration to undertaking quality assurance testing during the project. This helps manage costs and maintain project continuity.

Proven Solutions based on Science

At BCRC, we are revolutionising the way strata corporations and building contractors manage the treatment of magnesite-related defects. Our approach systematically addresses all issues to deliver a technically sound, cost-effective solution that meets the needs of property owners.

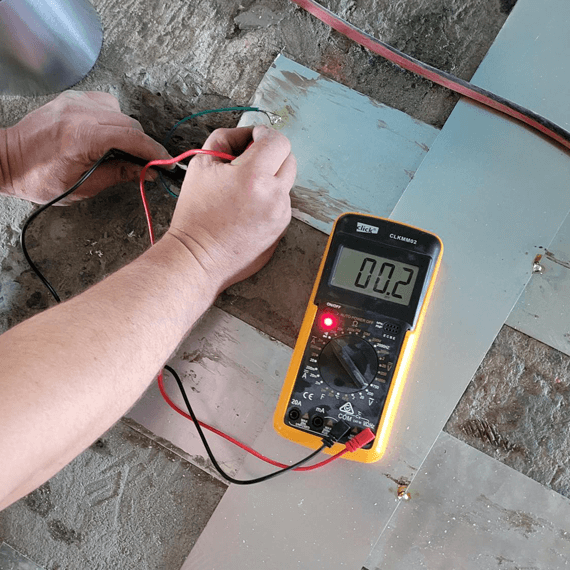

When inspecting and repairing multi-storey apartment buildings, we use Non-Destructive Testing (NDT) tools, chemical testing, residual service life modelling, corrosion detection techniques, and deterioration mechanisms, to assess corrosion risk and the long-term impact on serviceability.

In magnesite flooring where chlorides have penetrated the concrete slab to a critical degree, the risk of corrosion is high, leaving engineers with the option of removing the chloride-contaminated concrete or applying cathodic protection.

A Pioneering Approach to Treating Defects

Our innovative cathodic protection system only requires the removal of the fractured concrete and avoids having to break out and replace concrete, minimising the use of jackhammers. We then install a zinc anode in the form of zinc sheet strips on top of the floor slab. This stops corrosion in damaged areas and draws the chlorides away from the steel reinforcement, removing the risk of corrosion in nearby areas.

The amount of replacement concrete is minimised, making the solution faster, cleaner and cheaper. Carbon fibres can also be incorporated into the repairs to strengthen the slab where reinforcement corrosion is excessive.