BCRC are experts in the inspection and testing of all types of structures across all market sectors:

We have expertise in how structural behaviour impacts on the selection of test areas and how the exposure and structure interact and what is critical to service life of concrete structures. With over 30 years of experience in structural surveys, we have been involved in developing Non-Destructive Test (NDT) methods and writing the codes and recommended practices that define how inspection and testing should be undertaken.

We provide expert advice from durability, concrete, inspection and repair specialist consultants after inspection and testing, and develop your unique repair recommendations.

Inspection of structures (preliminary, routine, detailed)

BCRC have been involved in providing visual inspection of civil infrastructure including mines, railways, tunnels, floors, buildings, wharfs, bridges, and tanks. Our visual inspection service will identify defects including but not limited to cracking (active/inactive), drumminess, dampness, concrete pop-out, honeycombing, concrete spalling, concrete scaling, rust staining and physical damage including erosion etc.

Based on our extensive experience, we will help in preliminary, routine and detailed inspection for concrete structures.

Drone inspections

We provide drone aerial photography using remotely piloted aircraft systems (RPAS), including the DJI Inspire 2. Pixel Pilot holds a RPA operators certificate (ReOC), and our aerial photographers each hold a remote pilot licence (RePL) issued by the Civil Aviation Safety Authority (CASA).

Delamination surveys

We provide delamination survey by BCRC’s custom-made drummy testing roller and hammer-tapping in accordance with ASTM D 4580, to determine areas where the cover concrete has delaminated due to corroding reinforcement but does not yet necessarily show outward visual signs of cracking or deterioration.

Material Sampling and Testing

Extraction of samples

Testing of hardened concrete :-

BCRC use NATA-accredited laboratories with proven ability for specific tests. Tests are often in accordance with a BCRC specification.

Laboratory tests are used to support development of products for manufacturers or assessment of deterioration of existing structures.

The tests we provided for hardened concrete includes

- Compressive strength and density

- Chloride ion content

- Carbonation depth

- Sulphate ion content

- Cement content

- Calcium carbonate testing

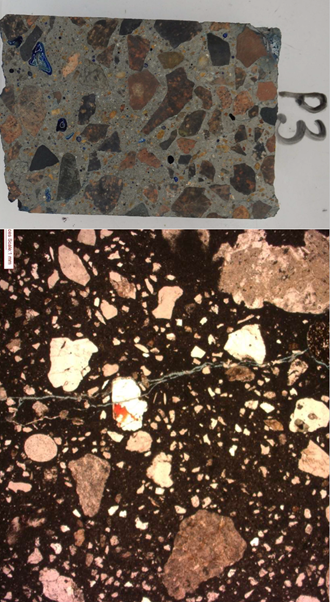

- Petrographic inspection

- Alkali aggregate reaction (AAR)

- Modulus of Elasticity

- Shrinkage

- Water absorption

- Bond (Pull Off)

- Water permeability

- Sorptivity

- XRD

- FTIR

- SEM

- Infrared

Corrosion field testing

Corrosion has massive cost implications to almost every industry that relies on metallic equipment and structures. A customized testing program will help to avoid any unplanned maintenance and the associated direct and indirect costs. BCRC can provide specific corrosion evaluations and protocols with recommendations and solutions based on best practices based on Australian and international standards to maintain the design life of your asset with the minimum maintenance and repair costs.

Corrosion field testing must be performed by specialized and well-experienced engineers and technicians. At BCRC, we have a team with the academic training, certifications, field experience and advanced testing tools to identify and evaluate corrosion mechanisms on site.

Monitoring of defects

BCRC provide monitoring systems for structural elements of civil infrastructure and manage installation, monitoring and assessment systems, including

- Strain gauges

- Linear polarisation Resistance meters

- Displacement transducers

- Potential cells

- Rack probes

- Temperature measurement

Structural health monitoring systems

BCRC provide structural health monitoring systems to ensure integrity and safety of civil infrastructures, including

- Detection of evolution of defects

- Determination of the locations of defects

- Identification of the types of defects

- Estimation of the performance and deterioration of structures.

Our professional consultants have expertise in data logger application, data transfer and management, data interpretation and diagnosis and reporting.

These are the tests and surveys we can provide you with:

- CP troubleshooting and assessment.

- Potential and current surveys with assessment on the structure and anodes.

- Direct current voltage gradient surveys (DCVG) and Close interval potential surveys (CIPS).

- Electrical interference testing

- Resistivity test.

- Physicochemical characterization of soils, water, and electrolytes.

- Half cell potential survey in concrete.

- Failure and root cause analysis in metals.

Our mission is to help you avoiding the failure of your asset or system and extending its life with the most efficient, competitive, optimized, and available solution.

Field testing not only covers identification of corrosion on site but also the troubleshooting of problems and issues present in the corrosion control systems put in place such as cathodic protection and coatings. BCRC has a wide range of tools and the professional expertise to assist on these requirements while providing you with a comprehensive report which will describe the guidelines and corrections to consider for the operation and maintenance of your corrosion control systems.

Key projects:

- RAAF Williamstown Building 11

- Lane Cove Tunnel

- Sydney Olympic Park Aquatic Centre

- UNSW swimming pool

- Austinmer Bathers Pavilion

- Bellambi Surf Saving Club

- Musswellbrook pool

- Crooked River bridge

- Japanese University (old Newcastle courthouse)

- Garden island

- West Dapto Road culvert

- Nowra bridge

- Marquesas twin towers building